Supply chain generally includes a set of processes aimed at supplying goods and services. This network includes suppliers, manufacturers or subcontractors, distributors and sellers who cooperate in a coherent way in order to fulfill our obligations towards the organization and increase the level of customer satisfaction. Supply Chain Management (SCM) at the macro level or logistics at the operational level is a set of actions to coordinate production, inventory management, transportation among system elements in a supply chain with the aim of achieving the best performance in the market. In supply chain management, the goal is effective and efficient integration between these components in order to minimize system costs and fulfill the operational needs of the organization, so that goods are produced/supplied and distributed in the right amount and at the right time and delivered to the customer.

Supply chain management is one of the most important management parts in any business. Manufacturing companies are involved in supply chain management in all these stages, from the supply of raw materials based on their orders or budgets, to the management of work-in-progress (WIP) goods and final products, and the circulation of these materials between work centers and multiple warehouses to the delivery of goods to the customer. Commercial and e-commerce companies are also involved in SCM and logistics processes in a different way, from finding suitable suppliers to supplying goods and quality control and sending the product and sometimes in the process of returning the items.

Optimizing the supply chain in any organization can create significant value for it. The existence of standard and optimal processes in purchasing and supply, sales, production, warehousing, shipping and supporting processes such as financial management and project management are all necessary to have an agile and dynamic supply chain. In addition to the organization being equipped with optimum process methods for doing works (Best Practices), it is necessary to use the appropriate information systems and the appropriate supply chain management software to create coordination between different units. On the other hand, it is necessary to support the necessary facilities for purchasing planning and production planning in the logistics management and SCM software of the organization. Because in the end, what is important is the timely fulfillment of the organization’s obligations and responding to the customer within the agreed time frame, which leads to customer satisfaction.

Supply chain management in Dynamics 365 Business Central software

Based on the general requirements mentioned in the previous section for supply chain and logistics management, we review the features of Microsoft Dynamics 365 Business Central ERP software in this area.

- Comprehensiveness and including all key components of the organization’s supply chain

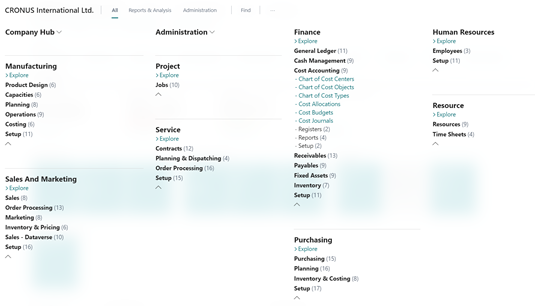

This ERP includes different modules that cover the entire key value chain of the organization. The modules are sales and marketing, purchase, warehouse and inventory, manufacturing and production, service and after-sales service, project management, and financial management are the modules in this system that are based on the scenarios of each business and Work is configured and implemented. All the key data of your business exists in a single and centralized database, and contradictions and redundancies are eliminated, and the organization has access to online and diverse reports in different parts of its supply chain. It is with the integration and optimal communication of these modules that the major issues of the organization such as cost, planning, cash flow management, etc. can be solved.

These modules include all required standard processes. In the sales module, there are basic sales data such as customers, price lists, marketing campaigns, customer history and sales documents such as quotes, orders, invoices, credit memo, sales return orders, marketing information, etc. In the purchasing module, supplier information and purchasing documents, as well as purchasing planning and MRP categories are similarly managed. In the manufacturing module there are production BOM, production routes, production details of each product such as scraps and rework, production capacities of the organization and QC results, and production documents such as production orders are also archived in this module. In addition, production planning is also embedded in this part, and finally, the warehouse module is used to manage all types of warehouses, shelving and zoning of warehouses, and generally manage the organization’s inventory so that the inventory is always up-to-date. Explaining and understanding each of these modules requires enough time and is beyond the scope of this article. In addition, other modules such as project management, service management and after-sales services are also complementary modules to model and cover the desired chain in organizations that have this topic. Accounting financial module should also be implemented as a key module in connection with other modules. In this system, each user has a specific role and as a result, a specific role, and according to his function in the chain of the organization, he is involved in the relevant operations and performs his duties at the appointed time.

- Standard processes based on APQC standard methods

When preparing a system, there is always a question whether the processes of this system are principled and optimal or we should follow certain process patterns. The Dynamics 365 Business Central solution as a standard ERP is based on the standard and APQC process methods, which is the recognized and approved standard in the field of best practices. Therefore, your processes in this system will be standard in the field of SCM, and with the standardization of processes, the agility and growth speed of the organization will increase.

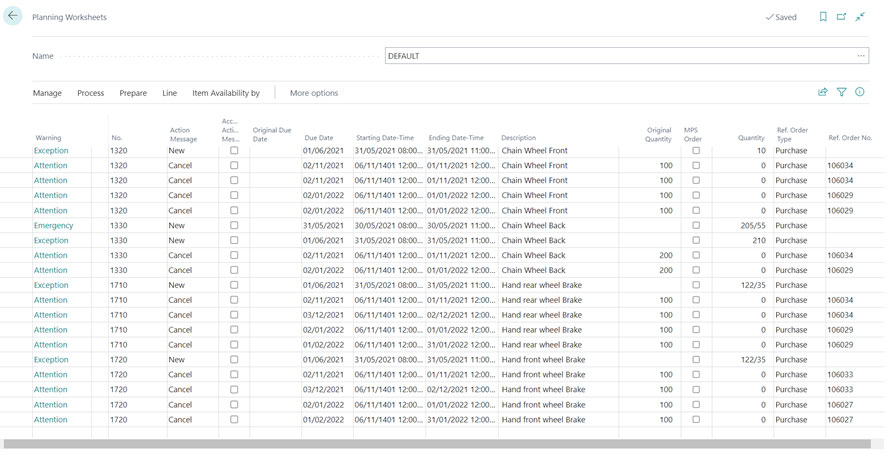

- A powerful engine for supply planning, production planning and movements planning

One of the most important concerns of managers is the timely completion of work in the supply chain. Timely performance of operational tasks such as purchasing raw materials, timely receipt of goods in the warehouse, performing tasks related to production and quality control, and finally transfers in the organization, so that the goods are ready to be sent to the customer at the promised delivery date and are sent at the right time. The Dynamics 365 Business Central solution has advanced planning capabilities in all of the above cases, and taking into account the committed delivery times, inventory on hand, goods on the way, orders in production, etc., it can provide optimal planning to carry out the general tasks of purchasing, production, moving and to carry out the assembly and thus the workflows in the organization are optimal and the work is done at the right time.

Management of transportation methods and internal and external movements

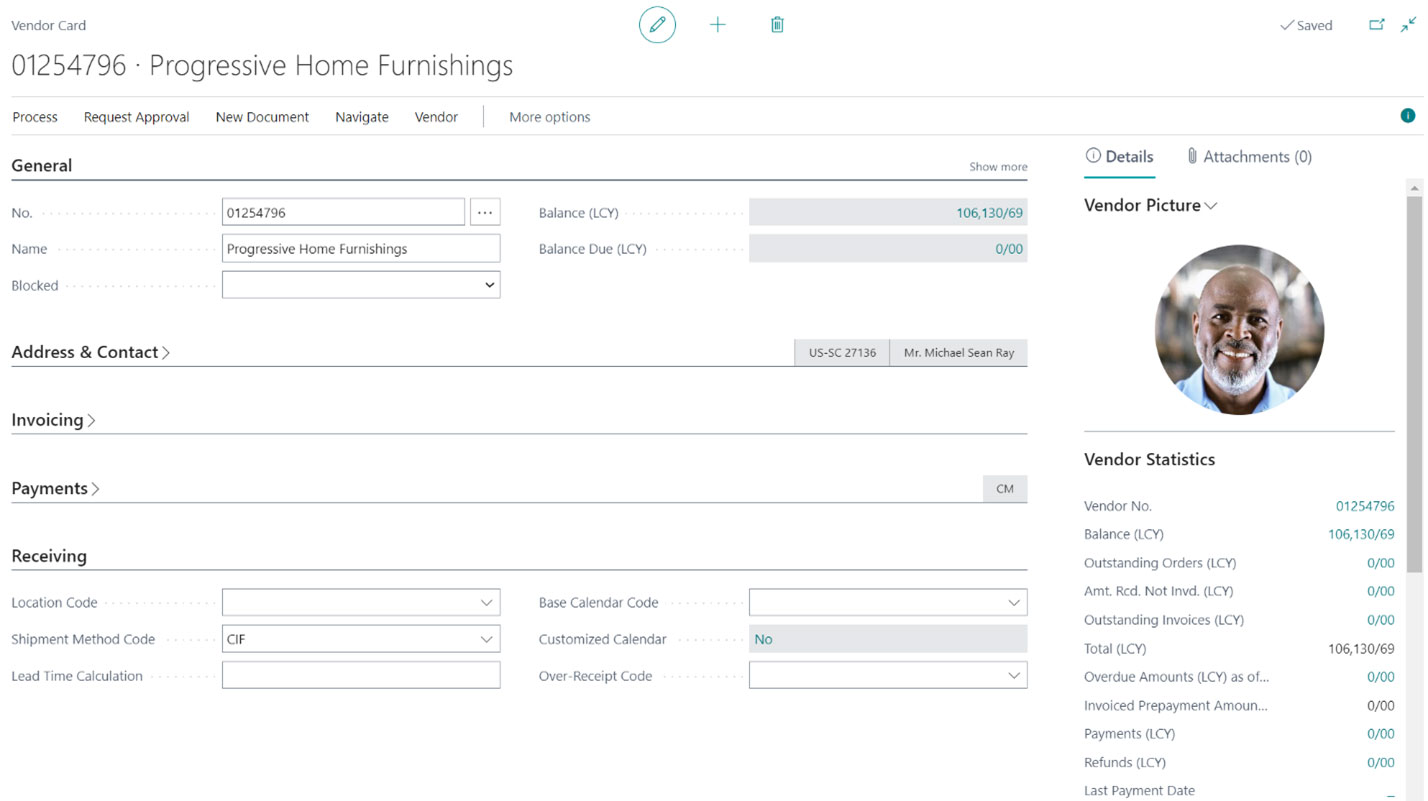

In the Dynamics 365 Business Central system, it is possible to define and choose various transportation methods and different Incoterms in relation to suppliers and customers. Therefore, the system can identify what the shipping method will be in each sales order or purchase order. Also, if needed, it is possible to define shipping agents so that, if needed, the corresponding agent along with its information can be recorded for each shipping case. It should be noted that any additional costs that occur during the supply chain (such as transportation costs, licenses, overheads, etc.) can be recorded and shared according to the desired method until the cost of the goods is correctly and with all costs included. Calculate.

- The possibility of defining the commercial logics required by each business at each stage of the supply chain

Every business needs to define certain logics in its supply chain depending on the nature of its activity. For example, many manufacturers or trading companies need to use serial numbers and batch numbers to track their activities in the supply chain. Some trading companies have direct sales from their suppliers, which means that the goods are sent directly by the supplier to the customer (Drop Shipment). Also, some businesses need to reserve inventory for some of their sales orders or production orders. In some businesses, it is necessary to connect all supply-side actions to a sales order so that later they can have proper reporting. These are some of the scenarios that are needed in the supply chain management of different businesses, and the required scenarios are not limited to these. But the principles and platform needed to implement all these scenarios are available in Dynamic 365 Business Central.

- Ability to connect to other hardware and software

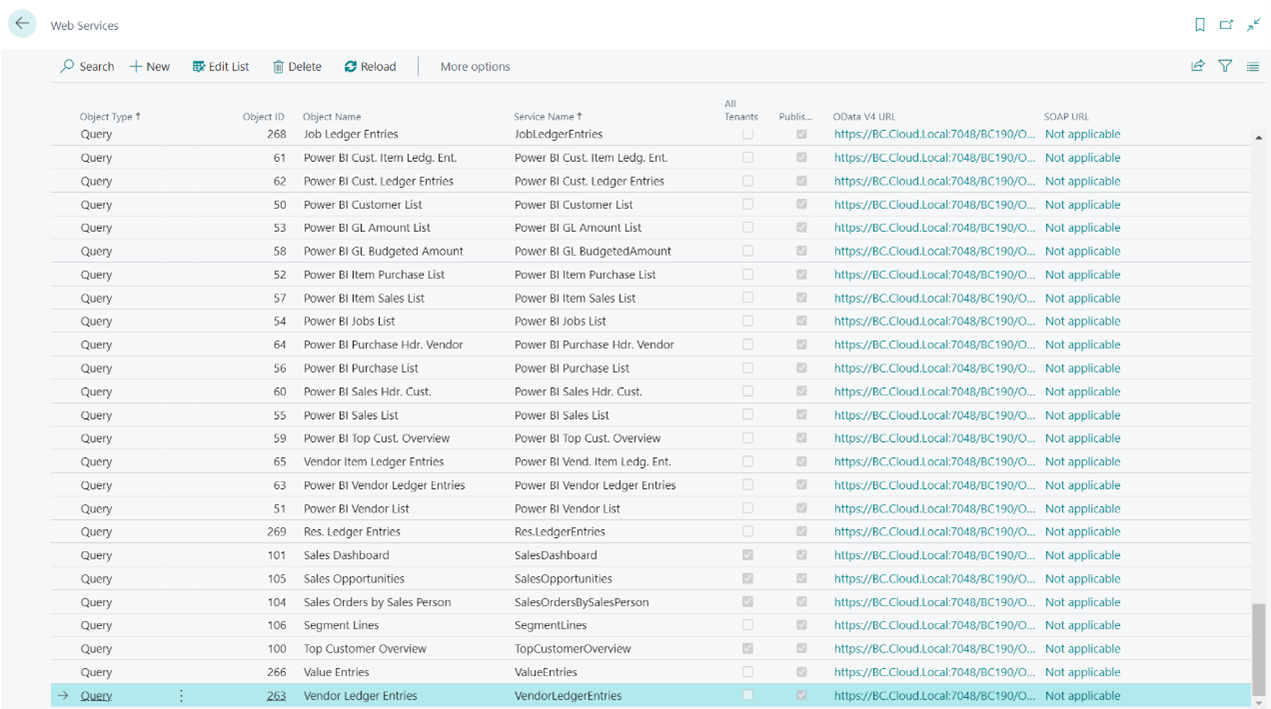

Some companies may use hardware such as barcode readers, RFID, counters, industrial handhelds, etc. for better management and better monitoring of their work process in the supply chain. Also, some organizations use organizational portals to place orders or communicate better with suppliers. On the other hand, some businesses have the nature of online sales and their starting point is to register a customer’s order in the e-commerce. Some organizations use a specialized system for routing, and some companies have special software for design. Considering that all these things are an important part of the organization’s supply chain, it is possible to establish the necessary connections between these systems and subsystems with the ERP system as the main back-office system of the organization. Dynamic 365 Business Central software has the ability to connect to all the above systems and practically has no restrictions on connecting to external software and hardware. Production of web service in this system is unlimited and unique. Therefore, it can give or receive necessary information to another system in a two-way manner at the desired points.

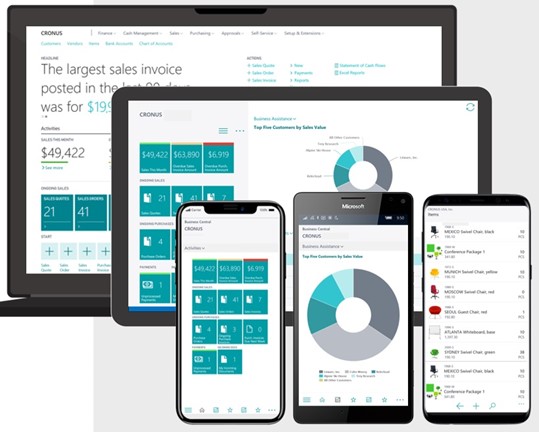

- Android and iOS application is ready

Dynamic 365 Business Central has a ready app for Android and iOS. Therefore, you can use it for representatives of the organization, visitors, project managers, etc., who need to enter information in different places and situations, this possibility is available to you through ERP system applications. Also, the managers of the organization can have access to the reports and forms they need in different conditions for approvals and monitoring of the work. In addition to the application, there is also web access, and the access levels are set very precisely and based on the role of people. It should be noted that different security protocols can be created to access the system to increase the security level of using the system outside the organization.

Conclusion

Supply chain management and logistics is one of the key aspects of any business, and suitable supply chain management software with optimal flows and the ability to monitor and control the entire chain can have a significant impact on the growing performance of the organization to meet the needs of customers and their satisfaction. The Dynamics 365 Business Central solution is a comprehensive and integrated solution based on process methods that can cover all types of organization scenarios in the field of logistics, and in addition to being equipped with a powerful planning engine, tracking goods along the chain, managing transportation methods, Online cost calculation and many other features that were briefly mentioned in this article; It is a flexible and reliable platform to cover the current and future needs of the organization in the field of supply chain management and logistics.