Microsoft ERP solution for Purchase and supply based on sales orders in trading companies (linkage of trading documents and operations):

Many trading companies and even manufacturing companies operate based on orders. In other words, they may not have any specific warehouses to deposit the end goods. Even if there are some warehouses, they are used for other purposes such as keeping inventories, maintaining assurance reserves, and retaining specific goods. Hence, organizational activities are initiated by taking orders from customers. When a sales order is finalized, the organization starts inquiring about the relevant suppliers. After different pro forma invoices are received, one or multiple suppliers will finally provide for the orders. In the end, the goods are delivered to customers once the transportation and logistics processes are finalized. The order is then closed. Moreover, financial documents such as the sales and purchase invoices are issued, and settlements are made in cash or by credit. Order-based manufacturing organizations also follow the same procedure; however, manufacturing operations should also be linked to an order in addition to the purchase operations.

An important problem facing many order-based organizations is to track and trace the entire path including the placement of a sales order in detail, inquiries received from suppliers, and the confirmed sales documents regarding a sales order and a sales invoice in addition to shipping goods to the customer, reaching settlements, and generating and keeping the relevant documents. Therefore, it is necessary to link the relevant sales and purchase documents with the delivery and shipment documents as well as the financial documents (and manufacturing documents for manufacturing companies). Thus, an order can be analyzed to determine what path has been taken to supply goods, what documents have been taken, what suppliers have been involved, and what details have been recorded. This path can also be tracked and traced reversely by analyzing every order to determine the sales order.

Furthermore, different organizations may deal with different conditions for shipment, delivery, and settlement with customers and suppliers. Some of the trading companies operate without any warehouses; therefore, the ordered goods are shipped directly to customers by suppliers (i.e., drop shipping or direct market sales). However, some other companies list the ordered goods once first in their warehouses and then ship them to customers. At the same time, other parameters such as customer credit or supplier credit, customer balance, and previous open documents of companies, which have financial and managerial characteristics, may make some differences in organizational or pricing affairs. This should also be taken into account in the sales and supply process of each order.

Although there is a logical need to manage and control operations in respective organizations, the necessary infrastructure is unavailable. If an organization has island systems and software suites, there will basically be no necessary connections between trading, financial, and warehouse operations and documents. If the essential systems do not exist, it is practically impossible to manage this process manually through Excel files. An organization should access the infrastructure with the following conditions in order to manage this problem properly on a systemic platform:

- The system should have sufficient integrity to cover the mainstream processes such as purchase, sales, warehouse affairs, and finance.

- The system should support the capability of linking trading and warehouse documents and the concept of goods reserve in general as well as document linkage.

- The system should support the capability of trading operations with and without warehouses (Drop Shipment)

- The system should support the track-and-trace capability through serial numbers and batch numbers.

- The system should support reporting based on different parameters to show the entire chain from the placement of an order to the supply and shipment of goods.

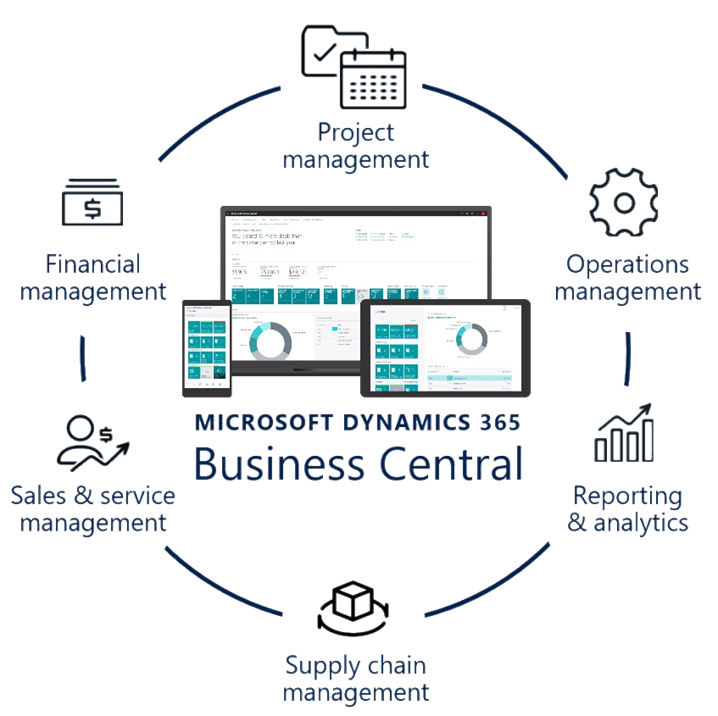

If the software infrastructure at your organization meets the above conditions, it will then be possible to track and trace trading orders within a connected framework and provide integrated reporting on the entire value chain. Usually, the integrated standard ERP systems such as Microsoft Dynamics 365 Business Central support these features.

The abovementioned features are now discussed with respect to the ERP D365 Business Central system to address the challenges.

Microsoft ERP Dynamics 365 Business Central Solution to Sales-Based Supply Problem in Trading Companies (Linking and Connecting Sales and Purchase Documents)

Dynamics 365 Business Central is a standard ERP developed by Microsoft, consisting of key business modules within an integrated framework. This ERP system provides appropriate infrastructure for macro challenges of an organization handled through the full system integrity. These challenges include the cost, purchase planning, production planning, and goods track-and-trace within the entire path. Like any other standard ERP system, Dynamics 365 Business Central needs to perform the processes of analysis and implementation based on organizational conditions and scenarios. Its processes are standard and based on the APQC.

The Dynamics 365 Business Central Solution and its features are now presented with regard to document linkage, trading operations, and the supply problem in general.

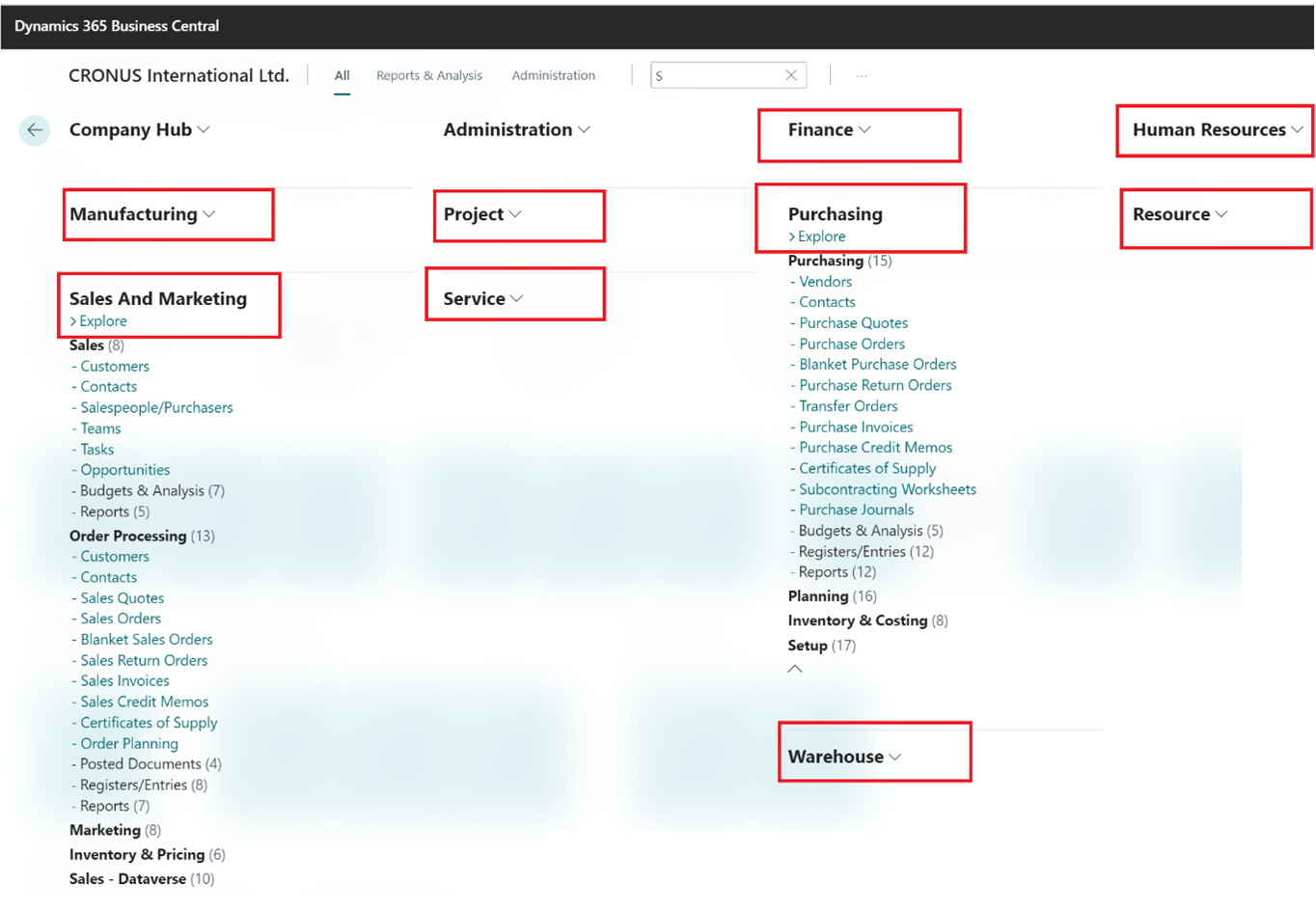

- System integrity to cover the mainstream processes such as purchase, sales, warehouses, finance, production, services, and projects.

In this system, all data of purchase, sales, and warehouses as well as other key processes exist on an integrated platform. The following figure presents the titles of system modules and some sample forms.

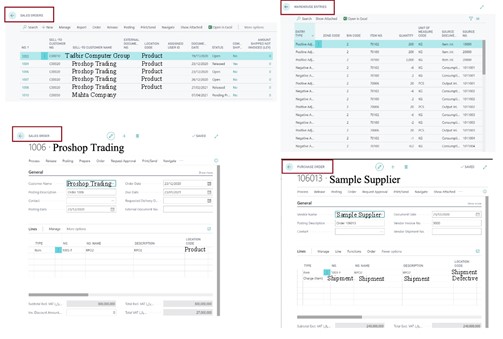

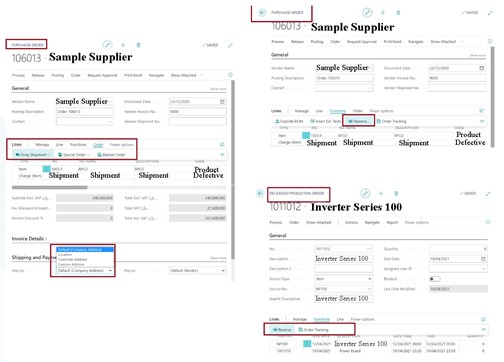

- Trading and warehouse documents linkage as well as concept of goods reserve and document linkage

In this system, it is possible to connect sales documents with all supply documents such as purchase, shipment, and warehouse. Generally, the system has two key features:

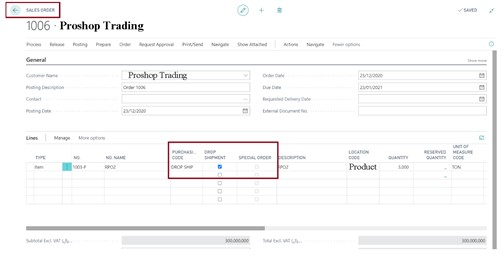

- Drop Shipment: This feature is used in cases where direct shipments are made by a supplier to a customer’s address (direct market sales)

- Special Orders: This feature is used in cases where the goods are shipped by a supplier to an organization, which should then ship the goods to a customer.

In both cases, sales orders can be recalled in purchase documents; therefore, sales and purchase operations can be linked. Furthermore, this feature is independently available for each line in a sales order. The concept of goods reserve is also provided to meet a specific sales order on different purchase and production forms.

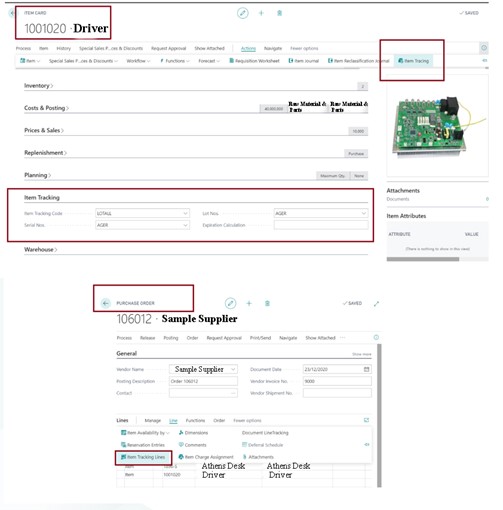

- Supporting the capability of tracking goods and batches through serial numbers and serial batches

A necessary piece of infrastructure for most organizations needing to link purchase, sales, warehouse, and financial documents as well as accurate reporting of supplied and shipped goods would be the tracking and coding infrastructure through serial numbers, batch numbers, or lot numbers of goods. This feature can be implemented differently at arbitrary levels in ERP Business Central.

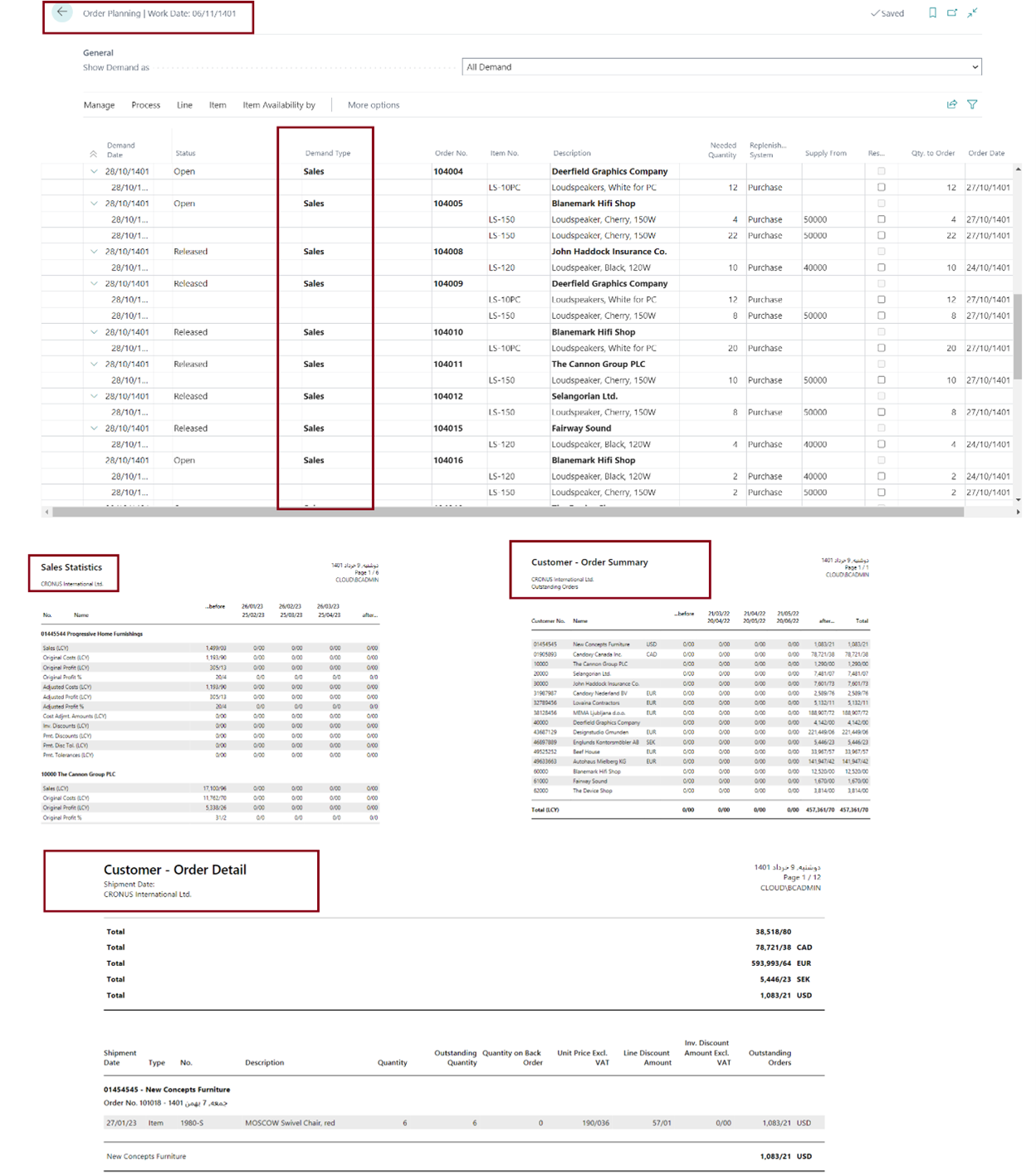

- Reporting based on different parameters to show the entire chain from order placement to supply and delivery

There will be no worries about the reporting layer if the mainstream operations of an organization such as purchase, sales, warehouse, financial, and production processes are performed on an integrated standard platform. ERP systems (e.g., ERP Business Central) are data-oriented solutions. This system includes more than 600 prefabricated reports in financial, purchase, sales, warehouse, production, and service modules. The system can also be employed by an organization to create dynamic reports as charts, lists, and pages. Hence, there will be easy access to the necessary reports.

Conclusion

Logically, order-based businesses need to link purchase and sales documents and generally perform sales and supply operations based on order sales orders in addition to tracking goods supply operations for a sales order and integrated reporting. This important goal cannot be achieved through island systems or manually without employing the right system infrastructure. It is essential to use an integrated system including all operational and key data of an organization to implement these processes and solve this problem. At the same time, such a system should also be able to support the features for connecting sales and supply operations. The concept of goods reserve and goods track-and-trace through serial numbers should also be possible. This system is also expected to support different transportation and shipment methods. Finally, all of these data should be provided online as managerial reports within an integrated framework. As discussed previously, these features and capabilities are presented properly by the Microsoft Dynamics 365 Business Central System, which is a good exemplar of the proper infrastructure and an operational solution to this organizational need. Furthermore, this problem has been implemented and executed on ERP Business Central at several companies.